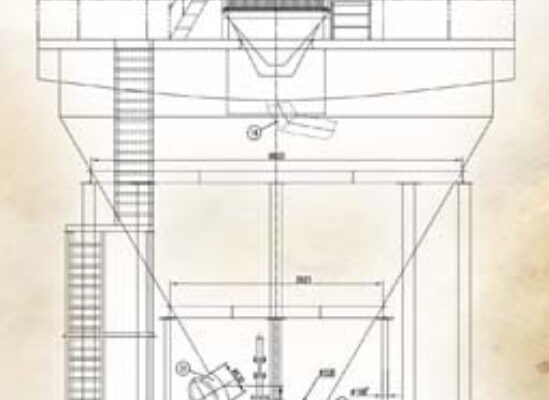

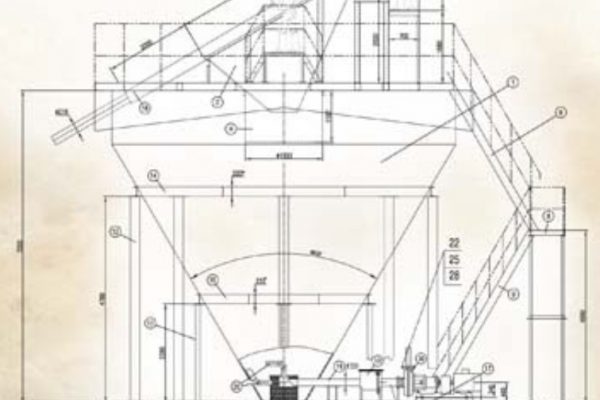

The 50 tons-per-hour heavy minerals processing plant is located in the Ukraine. The turnkey project encompassed electrical and control systems, civil engineering, process development, engineering design, construction plans, steel and electro-mechanical equipment are included as well as technical training.

Key design advances in gas re-circulation, high-pressure oil burner, and heat recuperation systems not only reduce emissions of greenhouse gases and dioxins from pelletizing and sintering plants but also generate savings in both capital and operating costs.

The new pelletizing core plant design encompassed a traveling grate indurating furnace area, an indurating furnace with a grate area of 768 m2, a double-deck roller screen, and a hearth layer screen, as well as six process-gas fans and four electrostatic precipitators to minimize environmental impact.

FEDINC provided detailed engineering design plans and specifications suitable for procurement and construction which included multi-disciplined coordination of Civil, Structural, Mechanical, Electrical, Piping, PFD, and P&ID engineering.